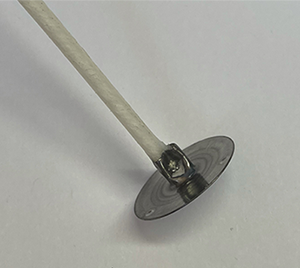

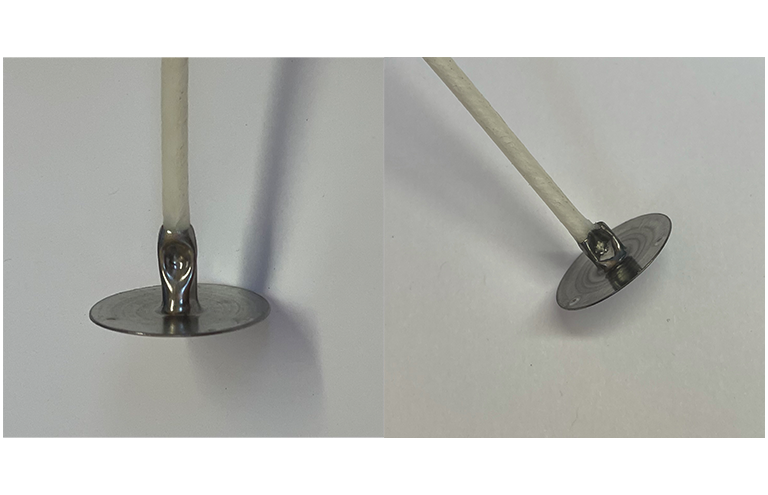

Wicks Unlimited developed two innovative crimping options to meet the performance demands of both candle manufacturers and end-users: non-puncture and puncture crimping. Non-puncture crimping enables candles to “shut off” while puncture crimping generates additional wax (fuel) flow that consumes all the fuel (wax) at the end of life, respectively. Both Non-puncture and puncturing crimping will help “shut off” the flame. The difference is that non-puncture will extinguish the flame as soon as it reaches the top of the neck. While all of Wicks Unlimited metal candle sustainers are manufactured from the highest quality tin-coated steel to inhibit corrosion caused by fragrance and essential oils, their end-of-life characteristics depend on their neck height and crimp type.

Metal Sustainers with Non-Puncturing Crimp

Wicks Unlimited signature non-puncturing crimping sustainer series enables manufacturers to develop candles that “shut off” at their end of life. This innovative sustainer design will meet all standard operating requirements for crimp hold. Candle manufacturers rely on non-puncture metal sustainers to reduce the overall thermal profile of a particular candle system to meet their customers’ preferences.

Wicks Unlimited signature non-puncturing crimping sustainer series enables manufacturers to develop candles that “shut off” at their end of life. This innovative sustainer design will meet all standard operating requirements for crimp hold. Candle manufacturers rely on non-puncture metal sustainers to reduce the overall thermal profile of a particular candle system to meet their customers’ preferences.

Non-puncture candle sustainer’s neck heights range from 6.0 mm and include safety neck sustainers with neck heights of 10.0 mm, 13.0 mm, 13.2 mm, and 14.5 mm to meet your specific safety requirements. Manufacturers can select from either 14.5 mm, 15.0 mm, or 20.0 mm base diameter(s). They can also take advantage of Wicks Unlimited’s wide selection of wick products since its wick insertion hole sizes include 2.1 mm, 3.0 mm, 3.8 mm, and 4.1 mm.

- Signature series sustainers with non-puncturing crimp “shut off” at their end of life.

- Available with neck heights of 6.0 mm, 10.0 mm, 13.0 mm, 13.2 mm, and 14.5 mm.

- Signature series sustainers with a non-puncturing crimp are available with 14.5 mm, 15.0 mm, and 20.0 mm base diameter(s)

- Wick insertion hole diameters range from 2.1 mm to 4.1 mm.

- Non-puncture crimp sustainers are manufactured from .010″ (0.254 mm) thick tin-coated steel that helps inhibit corrosion.

Metal Sustainers with Puncture Crimping

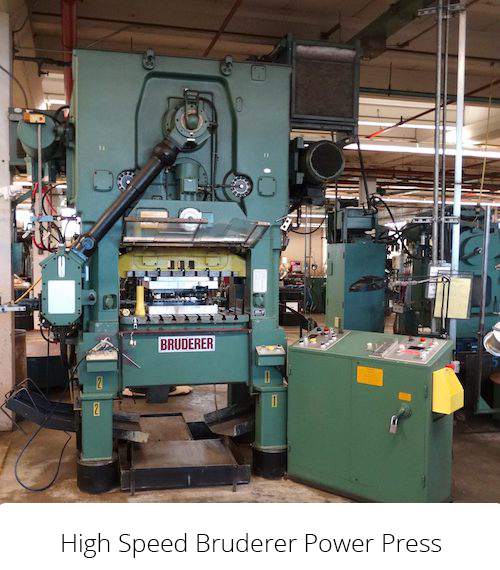

Precision high-speed equipment creates a piercing in the sustainer’s wall generating additional (fuel) wax flow at the candle’s end of life. Metal sustainers with puncture crimping enable manufacturers to develop candles that consume all the fuel (wax) as opposed to non-puncture crimping that leaves unconsumed wax at the end of life, respectively. Wicks Unlimited innovative puncture crimping provides a tight wick grip and simultaneously increases the crimp’s overall tensile strength.

Precision high-speed equipment creates a piercing in the sustainer’s wall generating additional (fuel) wax flow at the candle’s end of life. Metal sustainers with puncture crimping enable manufacturers to develop candles that consume all the fuel (wax) as opposed to non-puncture crimping that leaves unconsumed wax at the end of life, respectively. Wicks Unlimited innovative puncture crimping provides a tight wick grip and simultaneously increases the crimp’s overall tensile strength.

Metal sustainers with puncture crimping are available with neck heights of 6.0 mm and include safety neck sustainers with neck heights of 10.0 mm, 13.0 mm. 13.2 mm and 14.5 mm. Candle manufacturers can select base diameter(s) ranging from 14.5 mm to 20.00 mm. With wick insertion hole diameters ranging from 2.1 mm to 3.0 mm, manufacturers can choose from Wicks Unlimited’s diverse collection of wick products to meet their production requirements.

- Metal sustainers with puncture crimping are Wicks Unlimited’s best-selling sustainer series.

- Available with neck heights of 6.0 mm, 10.0 mm, 13.0 mm, 13.2 mm, and 14.5 mm.

- Standard series sustainers are available with 14.5 mm, 15.0 mm, and 20.0 mm base diameter(s).

- Wick insertion hole diameters range from 2.1 mm to 3.0 mm.

Manufactured from .010″ (0.254 mm) thick tin-coated steel that helps inhibit corrosion. - Sustainers with puncture crimping enable candles to consume all the fuel at the end of life.

- High-speed equipment creates a piercing in the sustainer’s wall generating additional (fuel) wax flow at the candle’s end of life.

Creating a Better Candle Experience with the Appropriate Crimp Type

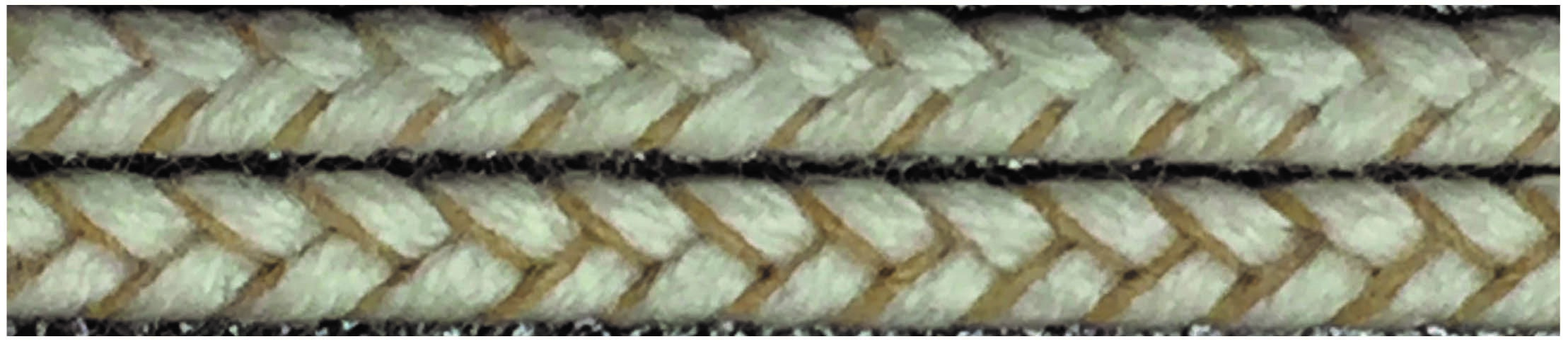

Take the guesswork out of selecting the appropriate sustainer crimp by partnering with the combustion specialists at Wicks Unlimited. We work with candle manufacturers during the candle formulation or troubleshooting phase to ensure their candle system uses the appropriate crimping option for optimal combustion. With over 450 different wicks stocked on-site, including cored and flat braided wick, 26 different candle sustainers, and an assortment of wick clip assemblies, Wicks Unlimited is the ultimate destination for all your combustion needs. Use the form below to contact Wicks Unlimited to discuss whether sustainers with non-puncture or puncture crimping are appropriate for your next production run.

Candle manufacturers understand their customers’ preferences, two of them being the temperature of the candle’s base and the amount of wax remaining at the candle’s end of life. The candle combustion experts at Wicks Unlimited work with manufacturers to determine the appropriate metal wick sustainer for their specific candle system to meet their customers’ expectations. Let’s explore why Wicks Unlimited candle sustainers are preferred by leading candle manufacturers globally.

Candle manufacturers understand their customers’ preferences, two of them being the temperature of the candle’s base and the amount of wax remaining at the candle’s end of life. The candle combustion experts at Wicks Unlimited work with manufacturers to determine the appropriate metal wick sustainer for their specific candle system to meet their customers’ expectations. Let’s explore why Wicks Unlimited candle sustainers are preferred by leading candle manufacturers globally. leading global manufacturer of standard and special eyelets, Wicks Unlimited wick sustainers meet the latest international quality standards and management systems stipulated in ISO 9001:2015. Wicks Unlimited manufactures and supplies 24 different sustainers of varying base diameters, neck heights, and hole diameters. They are made from the highest quality tin-coated steel to inhibit corrosion often caused by fragrance and essential oils, featuring an industry-leading .010″ (0.254) metal thickness.

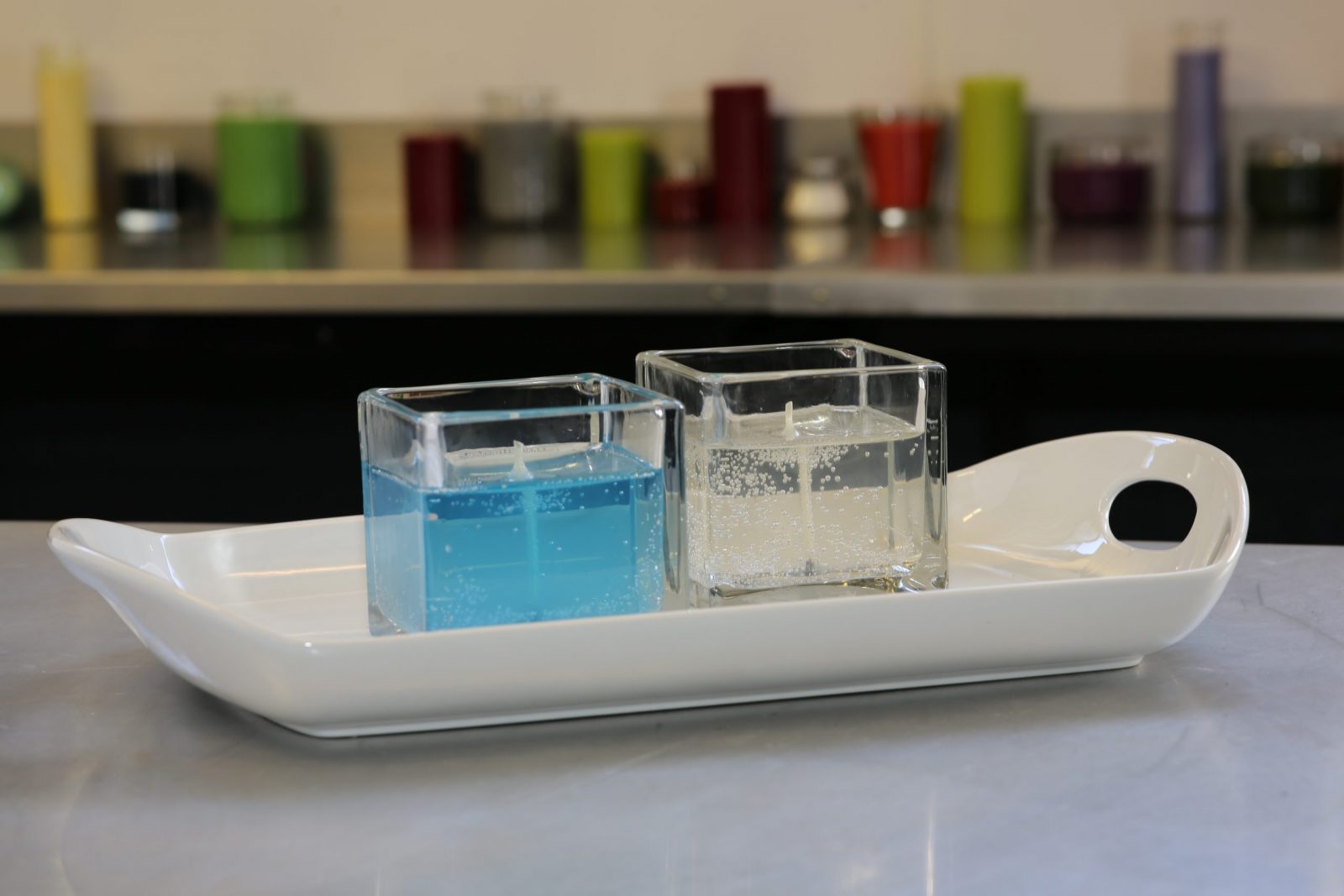

leading global manufacturer of standard and special eyelets, Wicks Unlimited wick sustainers meet the latest international quality standards and management systems stipulated in ISO 9001:2015. Wicks Unlimited manufactures and supplies 24 different sustainers of varying base diameters, neck heights, and hole diameters. They are made from the highest quality tin-coated steel to inhibit corrosion often caused by fragrance and essential oils, featuring an industry-leading .010″ (0.254) metal thickness. container. Wicks Unlimited offers 3.8 mm, 6.0mm, 10.0 mm, 13.0 mm, 13.2mm, 14.5mm, and custom wick sustainer lengths. The sustainer’s height determines the container’s base thermal profile, indicating an aggressive or a conservative system and the remaining amount of wax at the candle’s end of life. As a rule of thumb, sustainers above 10.0 mm can be considered safety sustainers, while sustainers below 10.0 mm are considered regular. It is important to note that the height of the neck determines how much wax remains on the container’s glass bottom at the candle’s end of life.

container. Wicks Unlimited offers 3.8 mm, 6.0mm, 10.0 mm, 13.0 mm, 13.2mm, 14.5mm, and custom wick sustainer lengths. The sustainer’s height determines the container’s base thermal profile, indicating an aggressive or a conservative system and the remaining amount of wax at the candle’s end of life. As a rule of thumb, sustainers above 10.0 mm can be considered safety sustainers, while sustainers below 10.0 mm are considered regular. It is important to note that the height of the neck determines how much wax remains on the container’s glass bottom at the candle’s end of life.