Candle manufacturers depend on Wicks Unlimited’s candle wick optimization services to prevent combustion issues from occurring in the first place or to solve existing combustion issues. Frequently, candle combustion issues are caused by either the manufacturer using the incorrect wick size, wick family, or a combination of both for a particular wax formulation, fragrance load, and/or container type.

Since each wick has unique burn characteristics, selecting and testing the wick type and size during pre-production is vital rather than rushing to production with an un-optimized wick. Even with extensive research and testing, candle combustion issues can come out of the blue. Please continue reading to learn what candle wick optimization is, when to complete it, and how to partner with Wicks Unlimited to optimize your next candle wick.

What is Candle Wick Optimization?

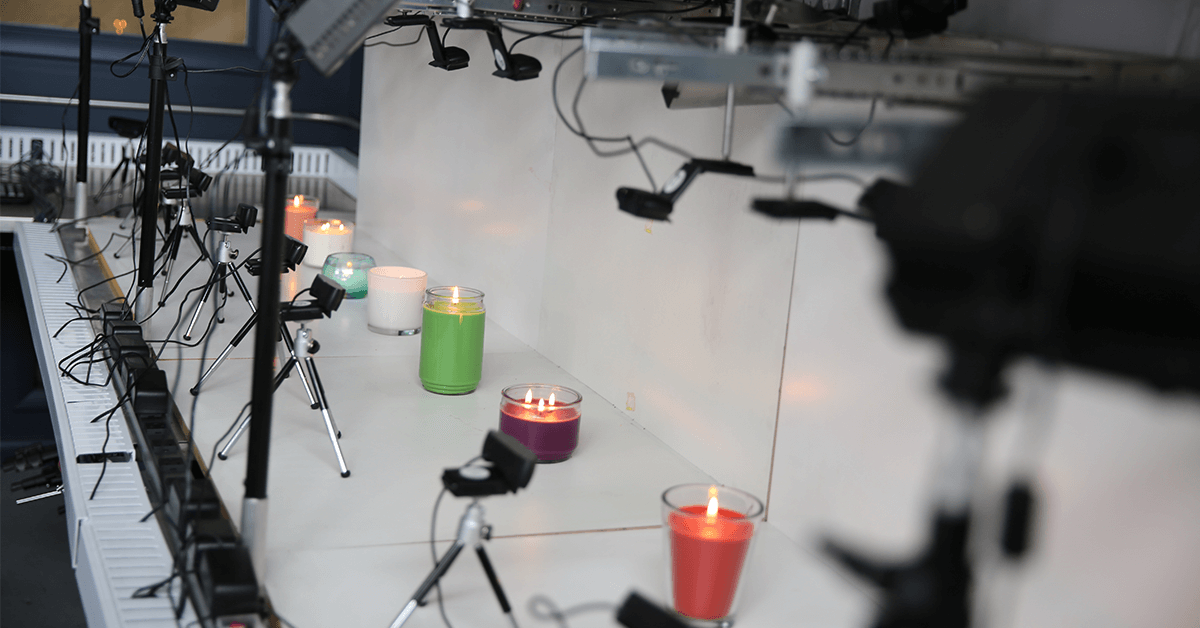

Candle wick optimization  services, like those performed at Wicks Unlimited, focus on three interrelated quality pillars: to ensure proper wick size and type for a particular candle system, improve candle performance, and improve candle safety. Using candle samples that the manufacturer ships to Wicks Unlimited, we complete four (4) hours of burn testing following the aforementioned quality pillars.

services, like those performed at Wicks Unlimited, focus on three interrelated quality pillars: to ensure proper wick size and type for a particular candle system, improve candle performance, and improve candle safety. Using candle samples that the manufacturer ships to Wicks Unlimited, we complete four (4) hours of burn testing following the aforementioned quality pillars.

Ensure Proper Wick Size & Type: The benefits of using an appropriately sized wick for a specific candle system cannot be overstated. Using your shipped wickless samples, the combustion experts at Wicks Unlimited select and test different types of wick. Once this is complete, we recommend an optimized wick that is the precise type and size for your specific candle application.

Improve Candle Performance: Wick optimization also improves the candles’ overall quality. Burn characteristics of an optimized wick include: a flame height that is the ideal size and below the 3″ safety threshold set by the ASTM for your specific container, minimal soot production, a wax pool that reaches the inside edges of the container and does not tunnel, consistent scent throw, and the actual burn time meets your expectations. In other words, wick combustion performance is optimal throughout the candle’s life.

Improve Candle Safety: Another benefit of professional wick optimization is improved candle safety. An optimized wick for a particular candle ensures that the candle’s flame height is not excessive. Excessive flame height is not only dangerous to the end-user and the brand’s reputation, it indicates incomplete combustion.Also, excessive heat from the flame can evaporate fragrance prematurely, reducing the candle’s overall scent throw.

Also, professional wick optimization prevents manufacturers from using a wick that is too small or large for a particular size candle. Candle wick that is too small is not optimal, and using a wick that is too large generates a larger than the average flame size that causes a deep burn pool that liquefies a large portion of the candle. Also, an oversized wick increases the candle’s surface area temperature to dangerously high levels. While candle manufacturers are responsible for final testing, safe candle combustion is at the heart of everything we do at Wicks Unlimited

When to Complete Candle Wick Testing & Optimization?

The simple answer as to when to complete wick testing and optimization is often. Since candle combustion is an exact science, even the slightest change to the formulation directly affects the candle’s combustion, overall performance, and safety. This below list is a good starting point for when to test and optimize a candle.

- During the development phase of bringing a new candle to market.

- Changing wick type and size

- Changing wax blends

- Changing fragrance type

- Increasing or decreasing fragrance load

- Adding or removing wax additives or enhancers

- Adding or removing dyes

As a rule of thumb, manufacturers need to optimize and test a particular candle after even making the slightest adjustment. Again, a good candle is a safe candle.

How to Partner with Wicks Unlimited for Wick Optimization?

Partnering with Wicks Unlimited for candle wick optimization is easier than you think. Follow the steps below to schedule and optimize your candle system today.

- Before contacting Wicks Unlimited, gather this vital information to help guide the conversation with our combustion experts.

- What type of candle are you seeking to optimize? (Paraffin, Soy, Pillar, Container, Votive, etc.)

- What is the size and type of wick you are currently using?

- What is the candle’s container size?

- How do you prefer your candle to perform in terms of temperature?

- Are you currently experiencing any combustion issues? If so, what are you experiencing?

- Is this an existing candle system, or is it in development?

With this information, contact Wicks Unlimited to schedule an appointment to discuss your burn objective and any combustion issues. - After speaking with a combustion technician, follow their instructions to ship three wickless candles for each fragrance or variation for optimization.

- Sit back and relax. Wicks Unlimited will recommend the perfect wick for your specific candle within two (2) to three (3) weeks, depending on candle size.

Contact Wicks Unlimited Today

Take the guesswork out of wick selection by partnering with Wicks Unlimited for wick optimization. Within weeks, we will help recommend the best wick for your candle and help you identify the combustion and burn issues you are experiencing. With over 450 different candle wicks, including cored, flat, and square braided wicks, from leading manufacturers such as Atkins & Pearce, Wedo, and Sao Vitor available for waxing, it is no wonder candle manufacturers depend on Wicks Unlimited.

selection by partnering with Wicks Unlimited for wick optimization. Within weeks, we will help recommend the best wick for your candle and help you identify the combustion and burn issues you are experiencing. With over 450 different candle wicks, including cored, flat, and square braided wicks, from leading manufacturers such as Atkins & Pearce, Wedo, and Sao Vitor available for waxing, it is no wonder candle manufacturers depend on Wicks Unlimited.

In addition to waxed wick on reels, Wicks Unlimited offers twenty-five (25) unique metal candle wick sustainers with regular and safety neck heights that enable candle manufacturers to create tabbed wicks from waxed wick on reels. Wicks Unlimited also manufactures and supplies an innovative self-centering sustainer that enables candle manufacturers to “drop and pour.” Also, all of our wick clip assemblies are made to your exact wax and wick length specifications. Use the contact form below or call 954-946-3500 to speak with a team member and partner with Wicks Unlimited for wick optimization.

*Please note that Wicks Unlimited only provides a wick recommendation. The candle manufacturer is responsible for final testing.

*Wicks Unlimited does not perform sensory tests.