Candle manufacturers partner with Wicks Unlimited for waxed wick on reels to increase their manufacturing capacity when using, or transitioning to, high-speed “in-line” cut, tab, and glue machinery to create candle systems that drive repeat customers. Wicks Unlimited’s proprietary waxing process gently forces air out of the raw wick. This step, known as de-gassing, saturates the entire wick, including the core, with wax. As a result, the wick will burn more uniformly, consistently, and predictably while simultaneously making it more robust to work with during production. One of the main reasons high-volume manufacturers prefer Wicks Unlimited’s waxed wick on reels is that they feature minimal ends. In other words, the waxed wick on the reel is made from one continuous piece of wick with a start point and an endpoint. Manufacturers will appreciate the simplicity of minimal ends during production, while end-users will appreciate its burn characteristics.

To meet the specific requirements of your particular candle machinery, Wicks Unlimited’s waxed wick features up to 3,000 yards (2,743 meters) per reel. All our reels are made from high-strength recycled cardboard to help candle companies reduce their carbon footprint and meet their sustainability targets. Wicks Unlimited’s extensive candle wick portfolio is just the beginning. Whether you’re a candle manufacturer looking for a new domestic-based wick supplier, transitioning to new machinery, or away from hand cut & tab production to automated machinery, Wicks Unlimited partners with you every step.

Why Partner with Wicks Unlimited as Your Waxed Wick on Reels Supplier?

Transitioning from Hand Cut & Tab to Automatic Machinery

Wicks Unlimited has helped hundreds of candle manufacturers transition to new machinery while minimizing production disruptions. The transition process is similar to when manufacturers first partner with Wicks Unlimited for waxed wick on reels. Once manufacturers select the specific machine for their production needs, Wicks Unlimited then works directly with the machinery manufacturer to ensure compatibility of our waxed wick on reels. In addition to working with the machinery manufacturer, the combustion experts at Wicks Unlimited, upon request, can review your wick selection to ensure optimal candle combustion. When production begins with the new machinery, manufacturers can focus on scaling production rather than worrying about the reel fitting the machinery or the candle’s burn characteristics. Wicks Unlimited handles those concerns during the transition process.

Access to Wicks Unlimited Technical Services

Whether you are a manufacturer developing a new candle or need combustion troubleshooting due to a change in your manufacturing process or supplier, Wicks Unlimited has you covered. Waxed wick on reel customers can access Wicks Unlimited’s state-of-the-art candle wick optimization and combustion lab to troubleshoot or solve any burn issues you are experiencing. Once our candle technicians understand your unique wick or candle combustion need, we begin comprehensive testing and analysis. After testing and analysis, we report our findings and make individualized wick and sustainer recommendations to help you find an optimized burn.

Access to Wicks Unlimited’s Make & Hold Program

Now more than ever, having a reliable U.S.-based waxed wick on reel manufacturer and supplier is vital for success. Wicks Unlimited customers participating in our Make & Hold program are guaranteed same or next-day shipping on their most critical candle components, including waxed wick on reels, wick-clip assemblies, and sustainers. Once candle manufacturers meet the minimum order quantities and are accepted for Wicks Unlimited’s Make & Hold program, they can then rely on it to solve just-in-time challenges, simplify their supply chain, and optimize production.

The Wicks Unlimited Difference

Creating a better candle experience for the end-user begins with partnering with a reliable waxed wick on reel domestic-based manufacturer and supplier, like Wicks Unlimited. With over 450 different candle wicks, including cored, flat, and square braided wicks, from leading manufacturers such as Atkins & Pearce, Wedo, and Sao Vitor available for waxing, it is no wonder candle manufacturers depend on Wicks Unlimited.

Creating a better candle experience for the end-user begins with partnering with a reliable waxed wick on reel domestic-based manufacturer and supplier, like Wicks Unlimited. With over 450 different candle wicks, including cored, flat, and square braided wicks, from leading manufacturers such as Atkins & Pearce, Wedo, and Sao Vitor available for waxing, it is no wonder candle manufacturers depend on Wicks Unlimited.

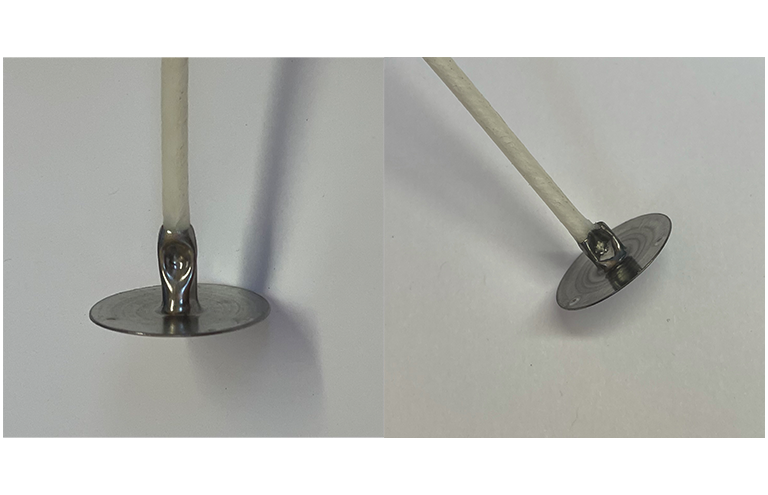

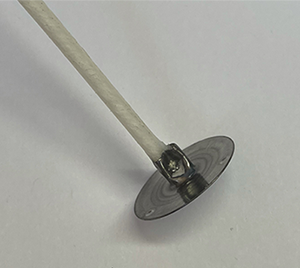

In addition to waxed wick on reels, Wicks Unlimited offers twenty-five (25) unique metal wick sustainers with regular and safety neck heights that enable candle manufacturers to create tabbed wicks from waxed wick on reels. To meet the burn preferences of the end-users at the candle’s end of life, manufacturers can select from either puncture or non-puncture sustainer crimping to create the ultimate candle experience. Wicks Unlimited also manufactures and supplies an innovative self-centering sustainer that enables candle manufacturers to “drop and pour,” and wick clip assemblies made to your exact wax and wick length specifications. Use the contact form below or call 954-946-3500 to speak with a team member to partner with Wicks Unlimited for waxed wick on reels.

Wicks Unlimited signature non-puncturing crimping sustainer series enables manufacturers to develop candles that “shut off” at their end of life. This innovative sustainer design will meet all standard operating requirements for crimp hold. Candle manufacturers rely on

Wicks Unlimited signature non-puncturing crimping sustainer series enables manufacturers to develop candles that “shut off” at their end of life. This innovative sustainer design will meet all standard operating requirements for crimp hold. Candle manufacturers rely on  Precision high-speed equipment creates a piercing in the sustainer’s wall generating additional (fuel) wax flow at the candle’s end of life.

Precision high-speed equipment creates a piercing in the sustainer’s wall generating additional (fuel) wax flow at the candle’s end of life.