Introduction to the Infinity Bond EasyMelt Glue Machine

The Infinity Bond EasyMelt glue machine is a benchtop hot melt adhesive applicator ideal for candle manufacturers looking to scale production and productivity cost-effectively. This versatile machine comes equipped with everything needed to get started immediately utilizing your air compressor or line. It is, best of all, compatible with all Wicks Unlimited candle sustainers and wick clip assemblies.

- Bulk Tank: A 1.5-liter hot melt tank

- Foot Pedal: For hands-free dispensing

- Nozzles: Various types for different application needs

- Built-In Timer: Ensures precise and repeatable dispensing

- Integrated Temperature Control Switch: Easy adjustment from 120℉ to 420℉ (50℃ to 250℃)

Key Features and Benefits

- Lightweight and Portable

The Infinity Bond EasyMelt machine is designed for portability. Its lightweight and compact design makes moving and positioning it within your workspace easy. This mobility ensures you can optimize your production line without being constrained by heavy, immovable equipment. - Convenient and Safe Operation

Refilling the bulk tank with RT2315 hot melt glue or another appropriate candle adhesive is straightforward and safe, thanks to the easy-to-open cap. This design reduces downtime and enhances safety, allowing operators to refill adhesive quickly and efficiently. - Adjustable Pressure and Flow

The machine’s pneumatic power system, coupled with adjustable pressure and flow settings, allows for precise control over the adhesive application. This level of control is crucial for maintaining consistent quality in candle production. - Fast Melting and Consistent Dispensing

With its efficient heating system, the Infinity Bond EasyMelt machine quickly melts candle glue, minimizing wait times and boosting productivity. The integrated electrical timer ensures the glue flow volume is consistent with each depression of the foot actuator, providing uniform and precise results across batches while minimizing wastage. - Easy Maintenance

The machine’s simple construction means that it requires minimal maintenance. This ease of upkeep reduces downtime and extends the machine’s operational life, making it a reliable addition to any production line.

Technical Overview

- The Infinity Bond EasyMelt glue machine operates on two main systems:

- Electrical Control System: This system manages the operation of the machine, including the integrated temperature control switch and shot timer. The temperature control switch allows operators to set and adjust the temperature of the hot melt tank within a range of 120℉ to 420℉ (50℃ to 250℃), accommodating various hot melt adhesive formulations.

- Pneumatic System: The integrated pneumatic and electrical power systems melt the glue efficiently and ensure smooth dispensing. The heating system is compatible with most hot melt adhesive formulations, including the RT2315 hot melt candle glue from Wicks Unlimited, with viscosities ranging from 500 to 20,000 CPS.

Contact Wicks Unlimited Today

The Infinity Bond EasyMelt glue machine offers a blend of efficiency, precision, and ease of use for candle manufacturers looking to scale their production. Its robust features and affordable pricing make it an excellent choice for enhancing production capabilities without significant investment. By incorporating this machine into your workflow, manufacturers can achieve consistent, high-quality results and meet growing demand with confidence.

With the addition of both the Infinity Bond EasyMelt glue machine and RT2315 hot melt adhesive to our product lineup, which includes over 450 different candle wicks, including cored, flat, and square braided wicks, and metal wick clip assemblies and sustainers, it is no wonder manufacturers depend on Wicks Unlimited for all their candle combustion needs.

Contact Wicks Unlimited to learn more and scale your candle production today using the Infinity Bond EasyMelt glue machine.

candle glue supplied by

candle glue supplied by  partnering with the combustion experts at Wicks Unlimited. From its superior surface adhesion while pouring to its thermal resistance towards the candle’s end of life, it is easy to see why candle professionals prefer RT2315 hot melt glue over other types of candle wick adhesives, such as wick stickers, cool melt glue, and super glue.

partnering with the combustion experts at Wicks Unlimited. From its superior surface adhesion while pouring to its thermal resistance towards the candle’s end of life, it is easy to see why candle professionals prefer RT2315 hot melt glue over other types of candle wick adhesives, such as wick stickers, cool melt glue, and super glue.

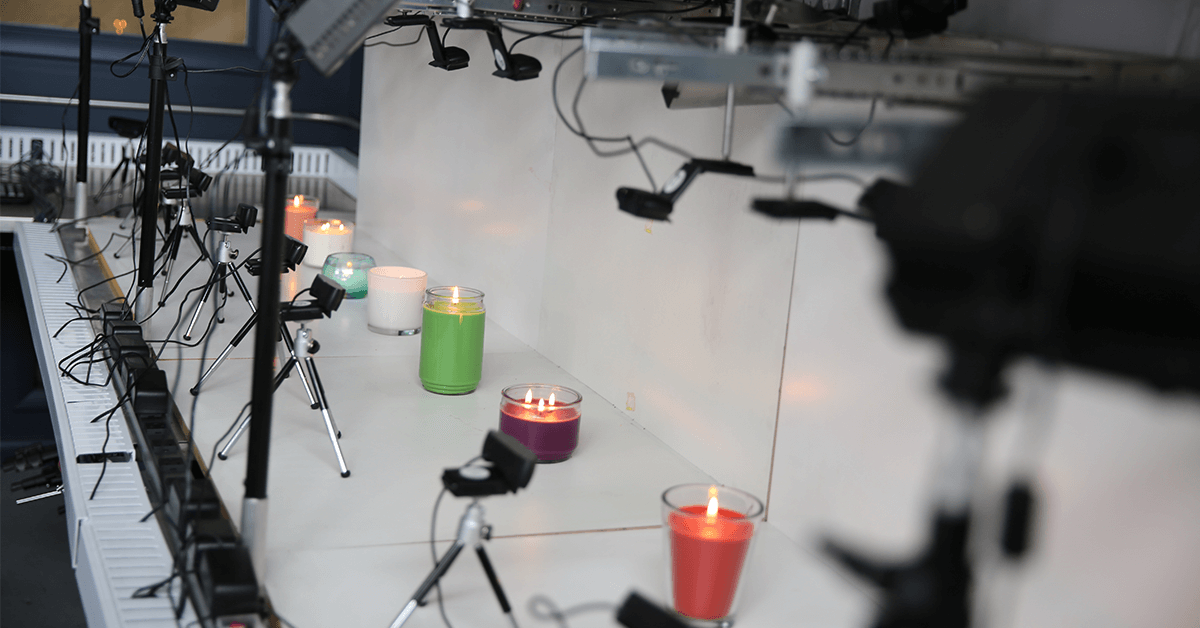

services, like those performed at Wicks Unlimited, focus on three interrelated quality pillars: to ensure proper wick size and type for a particular candle system, improve candle performance, and improve candle safety. Using candle samples that the manufacturer ships to Wicks Unlimited, we complete four (4) hours of burn testing following the aforementioned quality pillars.

services, like those performed at Wicks Unlimited, focus on three interrelated quality pillars: to ensure proper wick size and type for a particular candle system, improve candle performance, and improve candle safety. Using candle samples that the manufacturer ships to Wicks Unlimited, we complete four (4) hours of burn testing following the aforementioned quality pillars. selection by partnering with Wicks Unlimited for wick optimization. Within weeks, we will help recommend the best wick for your candle and help you identify the combustion and burn issues you are experiencing. With over 450

selection by partnering with Wicks Unlimited for wick optimization. Within weeks, we will help recommend the best wick for your candle and help you identify the combustion and burn issues you are experiencing. With over 450

The Importance of Using the Correct Candle Wick

The Importance of Using the Correct Candle Wick

Creating a better candle experience for the end-user begins with partnering with a reliable waxed wick on reel domestic-based manufacturer and supplier, like Wicks Unlimited. With over 450 different candle wicks, including

Creating a better candle experience for the end-user begins with partnering with a reliable waxed wick on reel domestic-based manufacturer and supplier, like Wicks Unlimited. With over 450 different candle wicks, including