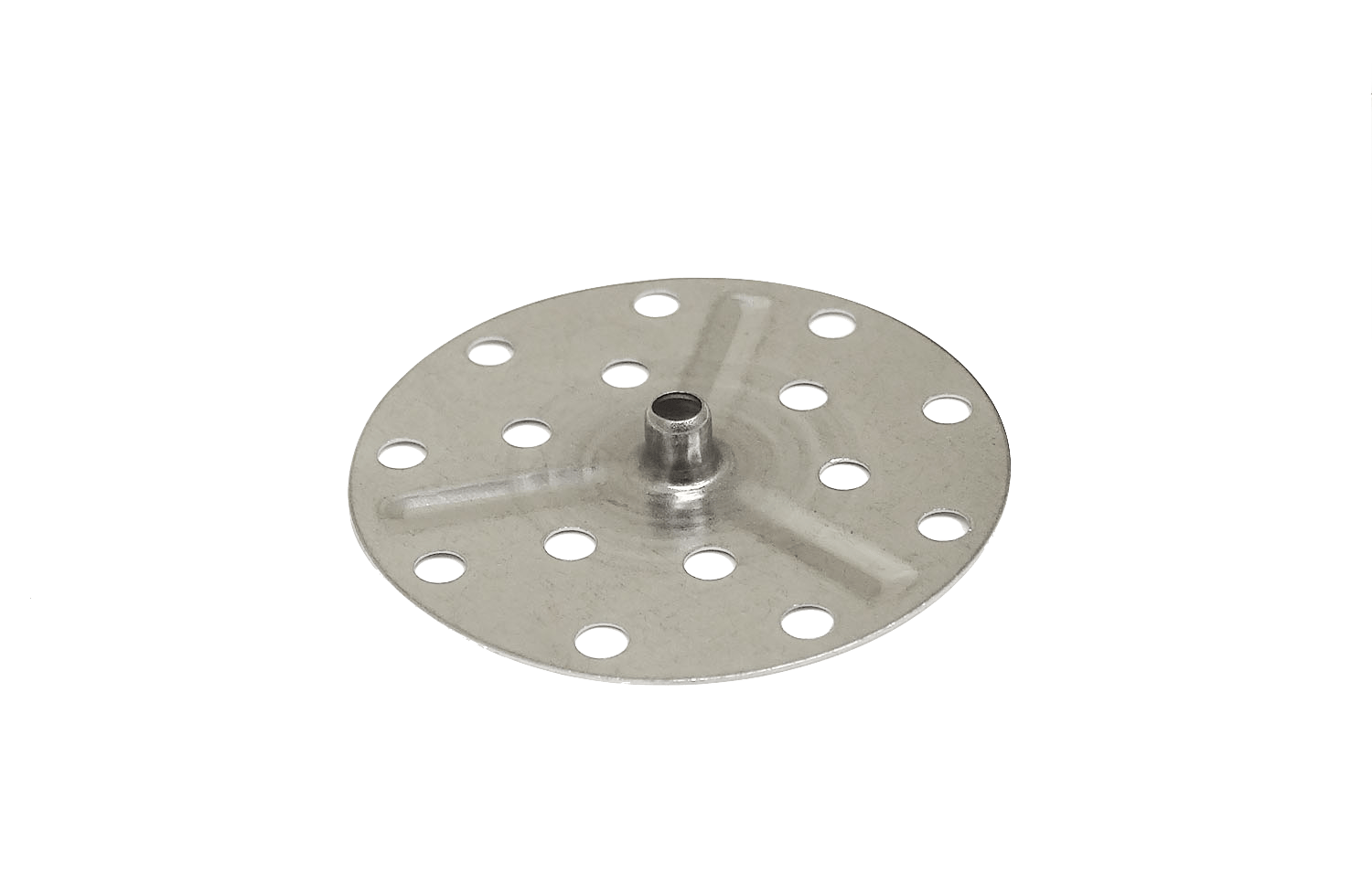

Wicks Unlimited’s innovative self-centering sustainers enable candle manufacturers to create tabbed wicks from waxed wick on reels and “drop and pour,” saving time and money. All of our sustainers are manufactured from .010″ (0.254 mm) thick tin-coated steel that helps inhibit corrosion and are preferred by leading candle manufacturers worldwide. Self-centering sustainers feature neck height(s) ranging from 3.8 mm to 6.0 mm, a base diameter of 31.8 mm, and wick insertion hole diameters ranging from 2.4 mm to 3.0 mm.

Candle manufacturers can select two crimping options for in-house cut and tab production runs: puncture and non-puncture 6.0 mm self-centering sustainers. The puncture crimp creates several small and one large piercing in the sustainer’s wall while still providing a tight wick grip and increasing the crimp’s overall tensile strength. Wicks Unlimited’s proprietary non-puncture crimping option enables candles to “shut off” at the end of life and will meet or exceed all standard operating requirements for crimp hold.